This was originally written by Robert Dalheim, an editor for Woodworking Network. This article was originally posted on the Woodworking Network website on October 2, 2020: click here for the original post. Thank you, Robert Dalheim and Woodworking Network for providing great information and letting us share this information with our community.

The Forest Products Laboratory (FPL) at the U.S. Department of Agriculture has developed a transparent wood that it’s calling the “window of tomorrow.”

In collaboration with the Univeristy of Maryland and University of Colorado, FPL researcher Junyong Zhu developed the material, which the USDA says has the potential to outperform glass in nearly every way.

“While glass is the most common material used in window construction it comes with a costly economic and ecological price,” writes the FPL. “Heat easily transfers through glass, especially single pane, and amounts to higher energy bills when it escapes during cold weather and pours in when it’s warm.”

Glass production also creates a heavy carbon footprint, with yearly emissions reaching 25,000 metric tons.

Transparent wood avoids these negatives.

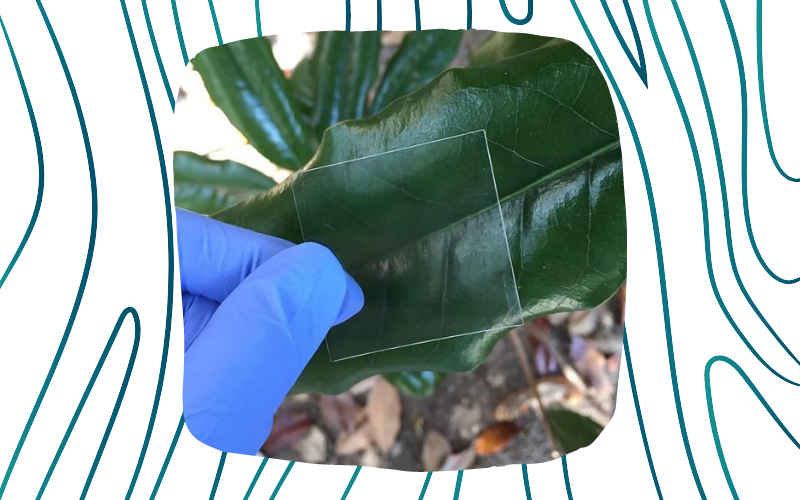

Transparent wood is created when wood from the fast-growing, low-density balsa tree is treated to a room temperature, oxidizing bath that bleaches it of nearly all visibility. The wood is then penetrated with a synthetic polymer called polyvinyl alcohol (PVA), creating a product that is virtually transparent.

The natural cellulose in its wood structure and energy-absorbing polymer filler in transparent wood means that it is far more durable and lighter than glass. It can withstand much stronger impacts than glass and, unlike glass, it bends or splinters instead of shattering.

“Switching to transparent wood could prove to be cost efficient as well. It is approximately five times more thermally efficient than glass, cutting energy costs. It is made from a sustainable, renewable resource with low carbon emissions. It’s also compatible with existing industrial processing equipment, making the transition into manufacturing an easy prospect.

“With all of these potential benefits for consumers, manufacturing and the environment, the case for transparent wood couldn’t be…clearer.”

Find out more about transparent wood.